By implementing a remote monitoring system, businesses can benefit from improved visibility into their operations, increased efficiency in maintenance and repair activities, enhanced customer satisfaction through faster response times, lower operational costs, and better asset utilization. Furthermore, a remote monitoring system can reduce downtime by quickly pinpointing problems with equipment before they become more significant.

Selecting the Right Remote Monitoring System

Choosing the ideal telemetry system is pivotal for ensuring seamless integration and optimal results. Consider the following factors when selecting the perfect fit for your business:

- Wireless data network coverage, cost, and longevity

- Ease of device installation and activation

- Hardware power requirements

- Scalability to accommodate future growth

- Availability of customer support resources and responsiveness

- 3rd party access to machine data through software APIs

Additionally, it is important to consider the size of your business and the type of equipment you are looking to monitor.

Implementing Remote Monitoring

Once you have chosen a remote monitoring system for your business, several steps must be taken to set it up and maintain it. Follow these steps to set up and maintain a successful implementation:

- Hardware installation and connectivity assurance

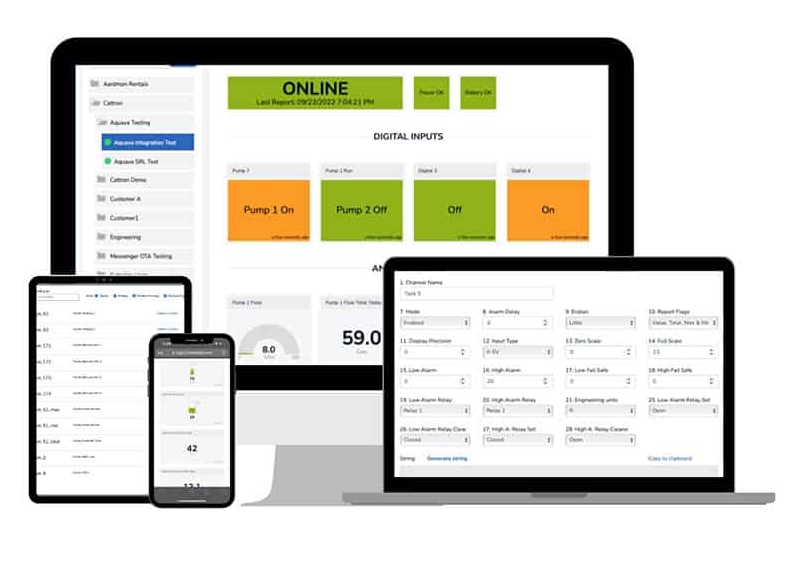

- Configuration of software features such as alarms and notifications

- Comprehensive training for sales and service personnel

- Regular system testing and performance evaluation

- Strategic planning for responding to any issues or triggered alarms

To maximize the remote monitoring system’s potential, consider the following operational tips:

- Real-time equipment performance monitoring with proactive adjustments

- Alert configuration for maintenance and repair needs

- Create user profiles for streamlined equipment data access

- Automate data collection and reporting processes to save time and effort

- Use data analysis software tools to identify operational trends

- Implement predictive maintenance protocols to reduce unplanned downtime

Maximize Equipment Performance through Telemetry

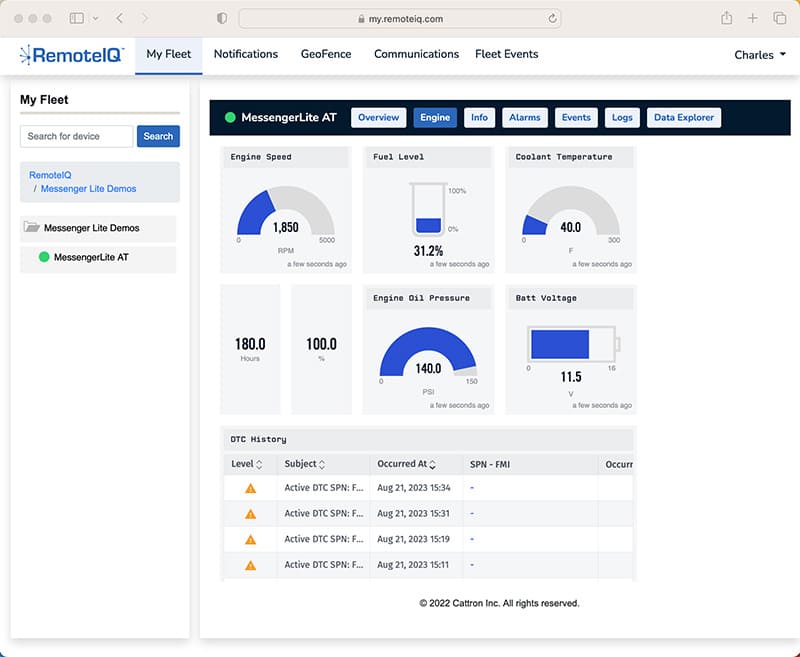

Discover the capabilities of remote monitoring systems that bolster operational efficiency while curtailing costs. Telemetry can increase visibility into operations, help streamline processes, and improve asset utilization. Additionally, they empower businesses to anticipate and avert potential issues, mitigating costly downtime.

Explore our Messenger remote monitoring product portfolio that seamlessly integrates with the RemoteIQ™ cloud-based monitoring service to optimize customer operations.