You may think wine is just wine and has been for centuries. In the age of technological advancements, wineries are not left behind.

Today, we’re focusing on a game-changer in wine production – using industrial remote-control systems to operate wine pumps.

This innovation enhances efficiency, reduces oxygenation, and improves the quality of your favorite wines.

Understanding Industrial Remote Control Systems

To better understand the impact of industrial remote control systems in wineries, let’s first understand what they are and how they work.

What is a wine pump?

A wine pump is a versatile industrial pump, often mobile, used in wineries for a variety of different tasks in and around wineries:

Render of a wine pump

- To gently transport grapes without breaking them.

- To (over)pump must, the freshly pressed but not yet fermented juice of grapes.

- To transport wine from tanks towards storage, cooling, blending, and bottling.

- Pumping out sediment remaining in the tanks.

The wine pump is a versatile compact machine that ensures that the quality of the wine remains as good as possible. Therefore, the pumps must meet high standards with unique requirements so that the grapes and liquids do not shake and pulsate too much during pumping (transport). All of this will affect the quality of the wine.

How does it work?

Wine pumps use a wireless transmitter to remotely operate the pumps used in wine production. The system works through radio frequency, which allows for seamless communication between the transmitter and receiver.

With this technology, operators can start, stop, and adjust the speed of pumps from a safe distance. This eliminates the need for manual operation, reducing the risks associated with exposure to chemicals and other hazards in the winery.

Reducing Oxygenation

One of the most significant challenges in wine production is oxygen exposure. When wines are exposed to oxygen, they can develop undesirable flavors and aromas. To prevent this, wineries must minimize the contact between wine and air during production.

Industrial remote control systems play a crucial role in reducing oxygen exposure. By being able to remotely operate pumps, operators can adjust speeds as needed to maintain constant levels of flow. This ensures minimal agitation of the wine, which reduces the risk of oxygenation. This feature ensures your wine maintains its freshness, flavor, and color, offering a superior tasting experience.

Enhancing Efficiency

The use of industrial remote control systems in wineries has significantly improved efficiency. With traditional methods, operators had to physically move from one pump to another to monitor and adjust their speeds. This process was time-consuming and often led to delays in production.

With remote control systems, operators can now control multiple pumps simultaneously, making the process faster and more streamlined. This not only saves time but also reduces labor costs for wineries.

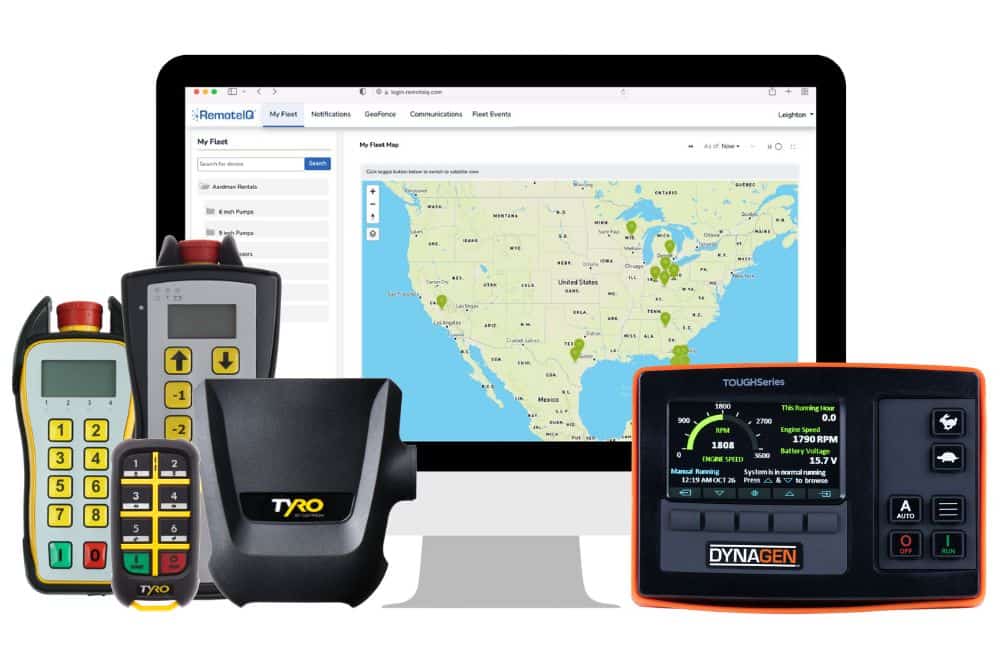

Tyro wine configurations

Tyro offers a wide range of suitable products for the wine industry. We are passionate about providing solutions that enhance efficiency and productivity. Our upcoming new generation of industrial remote control solutions. the Tyro 2S products are designed with these goals in mind. Some examples of upcoming products that can be used in wineries or similar applications:

Musca 2S

Compact remote with up to 6 functions

Aquarius 2S

Compact IP68 receiver

Pyxis 2S

Customizable up to 8 buttons

Scorpius 2S

Customizable receiver

Musca 2S

The solid compact Musca 2S has an ergonomic design and is suitable for up to 6 straightforward functions with haptic tactile buttons. Exceptionally suited tasks such as pump on, pump off, increase speed, and decrease speed.

Aquarius 2S

The Musca 2S can be connected to the waterproof IP68 Aquarius 2S receiver. Just like the handheld remote a compact, solid device. Thanks to its casted housing extremely durable to withstand all external influences.

Pyxis 2S

Would you like more features? Then the Tyro Pyxis 2S system could be your best choice. Up to 10 buttons and several enhanced options, such as an optional emergency stop button and/or display to view essential values directly transmitted from the pump.

Scorpius 2S

A real powerhouse of a duplex receiver. Available in multiple versions to suit the needs of your application and handheld remote. Think of optional analog and/or digital in/outputs, tilt sensors, or RS232/CAN-bus capabilities. This is all still in a very compact casted waterproof housing. That’s the Scorpius 2S.

Conclusion

If you’re in the winery business and looking for ways to innovate and improve your operations, reach out to us. Let’s raise a toast to technology and better wine!

Industrial remote control systems for wine pumps have revolutionized wineries by enhancing efficiency, reducing oxygenation, and improving wine quality. With wireless radio technology, operators can remotely control pumps from a comfortable distance, leading to increased productivity and cost savings for wineries. As the industry continues to evolve, we can expect to see further advancements in remote control systems and their impact on winery operations.

Remember, the future of winemaking is here, and it’s remote-controlled! Cheers to the future of wine production!

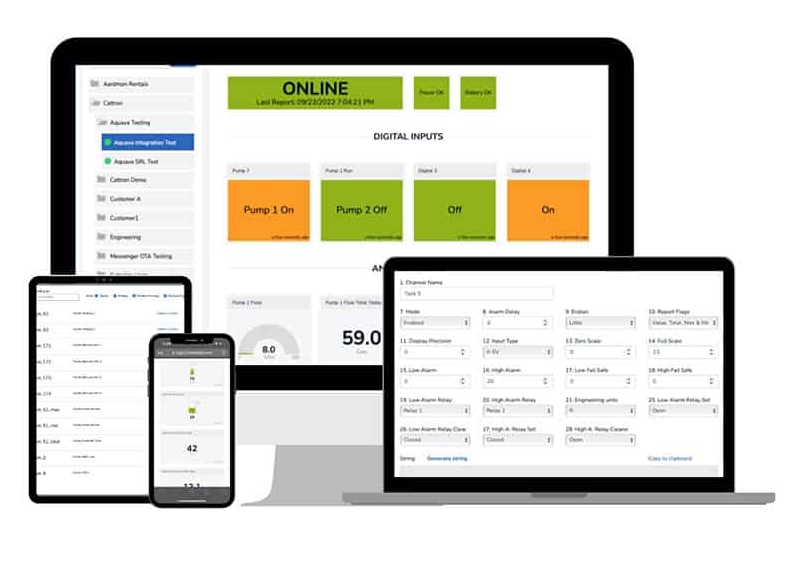

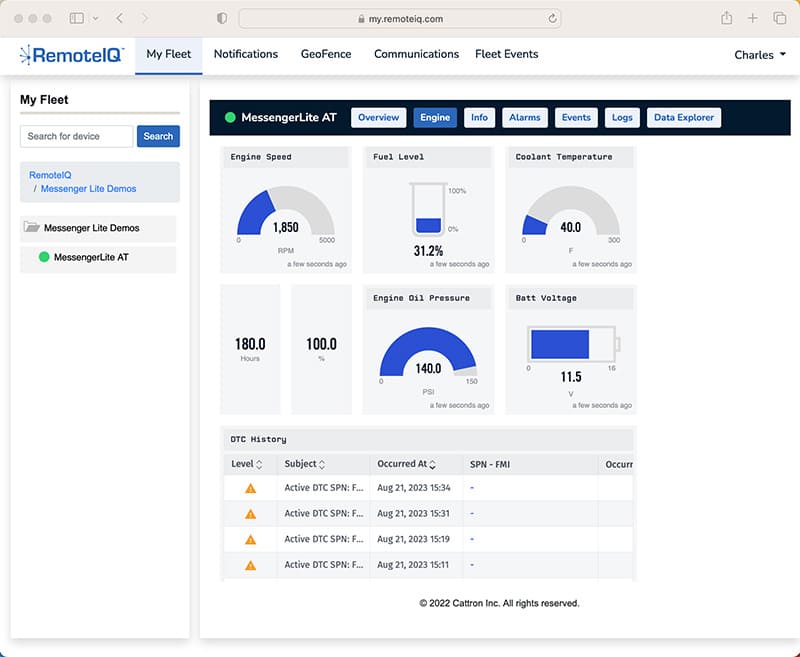

Enhance equipment performance and streamline operations with the power of telemetry. Remote monitoring technology enables businesses to monitor and manage large, dispersed equipment fleets from anywhere. It allows you to remotely track your equipment, measure performance, and receive critical warnings and alerts. The result is maximized equipment uptime and greatly reduced field service labor and overhead costs.

Enhance equipment performance and streamline operations with the power of telemetry. Remote monitoring technology enables businesses to monitor and manage large, dispersed equipment fleets from anywhere. It allows you to remotely track your equipment, measure performance, and receive critical warnings and alerts. The result is maximized equipment uptime and greatly reduced field service labor and overhead costs.