A sprinkler system generally consists of a powerful pump – for example, the pump that pumps out the water from a ditch. When the computer indicates that the spray gun has finished with its program, the pump is expected to stop immediately.

This is done with the help of an Aquarius transmitter and an Aquarius receiver.

Aquarius M2M system

The Aquarius is programmed as a transmitter that receives a signal from the spray gun and sends it to the pump (at a distance of 700 meters!) which then directly shuts down. All this without human intervention, without the touch of a button.

This solution comes from the demand for a stable communication signal that the user can always trust. Tyro Remotes offers this guarantee with the M2M control systems based on the latest radiographic technology.

Machine-to-machine

The term ‘M2M’ or ‘Machine to Machine’ stands for the communication between machines without any human intervention.

Unleashing Efficiency and Safety for Your Operations

When it comes to system design and integration for mobile equipment, we are the industry leader. We take a comprehensive approach, partnering with the Engine OEM and the Machine OEM to enhance productivity, maximize uptime, and prioritize safety.

Our integrated solutions cater to the needs of both the machine OEM and the end user. For instance, we offer durable plug-and-play subsystems, including engine control panels with variable speed capabilities, wireless machine control, and cloud-based remote monitoring and diagnostics. Our CANbus-based hardware seamlessly ties it all together with optimized wire harnesses, sensors, and HMI products.

No matter your mobile equipment application, we’ve got you covered. We start by thoroughly understanding your requirements, specifications, and scope of work. Next, our team of experienced application engineers, project managers, and product experts will collaborate with you throughout the development process.

Mobile Equipment Applications

TRAILER MOUNTED EQUIPMENT

Airport ground support

Cable reels

Industrial cleaning

Road maintenance

Water pumps

Wood chippers

WORK TRUCKS

Aerial work platforms

Bulk feed trailers

Car transport

Concrete mixers

Concrete volumetric mixers

Digger derricks

Fire apparatus

Hook lifts

Knuckle boom cranes

Service truck cranes

Tow recovery

Trailer axle steering

Vacuum trucks

CONSTRUCTION EQUIPMENT

Excavators

Paving equipment

Rock crushers and screeners

Wheel loaders

MINI CONSTRUCTION & FORESTRY

Forwarders

Harvesters

Horizontal boring

Skid steer loaders

Stump grinders

Trenching

AGRICULTURE

Bale wrappers

Harvesters

Mulchers

Planters

Seed tenders

Sprayers

Turf placement

MINING

Conveyors

Drills

Feeder breakers

General dewatering

Generators

LHDs and Light towers

Network/Communications

Rock breakers

Roof bolters

Shotcrete sprayer

Wheel dozers

Service vehicle equipped with Tyro remote controlAutomotive, Hydraulics, Industries, Medical, Off Highway Vehicle, Oil and Gas, Robotics

Arcxis, located in Belgium, specializes in fitting out commercial vehicles. For one of their customers, they have fitted out a service vehicle that uses a remote control by Tyro Remotes.

The commercial vehicle is fully equipped to provide maintenance and servicing for semi-trailers and trailers on the road should they run into problems. This vehicle is equipped with hose reels for compressed air, gas, and oxygen so that welding or other necessary repairs can also be carried out on the road.

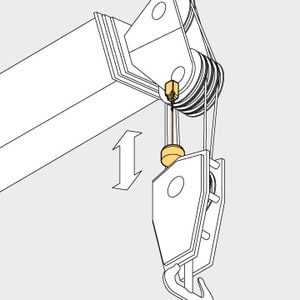

The Pyxis 8F remote control in combination with the Aquarius 10F receiver is specifically configured for the 24V cable reel. The cable reel with 20 meters of cable and 13-pin plug is used to control the lighting on, e.g., a trailer. With the remote control in your hand, you can stand behind the trailer to easily and efficiently test the lighting.

With a quick installation, it is an easy way to remove the headaches associated with the wires, rusted contacts, and loose springs of traditional ATB systems.

This wireless system eliminates both the cable reel and the Anti-Two-Block switch and the headaches associated with them. The self-contained switch is immune to mechanical failures and water damage since both the switch and the receiver are designed with solid-state components, which are fully encapsulated; the system is designed to be as hassle-free as possible. There’s no need to worry about the potential for a cable being broken by branches or other objects, and no need for a cable reel.

This is also a perfect solution to eliminate the corrosion factor in the reel contacts and their loose springs. Installation is as simple as mounting the wireless switch at the boom tip and installing the receiver at the base of the boom. This simple installation allows OEMs to reduce manufacturing costs by removing brackets, wire guides, and the associated labor.

Systems: 900MHz System | 2.4GHz System | Anti-Two Block Switch

| Wireless Anti-Two Block System | Wireless 2.4GHz Anti-Two Block Switch Transmitter System |

About Us

At Anderson Control, we are dedicated to providing top-notch automation solutions and precision control technologies. Founded in 1982, we have built a reputation for excellence in delivering high-quality products and services tailored to meet the needs of diverse industries. Our extensive experience and commitment to innovation empower us to offer a comprehensive range of sensors, motion control devices, encoders, and industrial controls. We strive to exceed customer expectations by combining cutting-edge technology with exceptional support, making us a trusted partner in your automation journey.

Quick Links

Great Deals!

Contact Us

Do you have a question or looking for a specific product? Let us help!