Dependable electronics are an absolute necessity in hazardous environments. However, the combination of combustible gases or dust with an arc or a spark from these products can potentially cause devastating fires or explosions. Whether you are at the chemical plant, on your oil platform or offshore drilling rig, in your mill, or somewhere equally as dangerous, all of your equipment is likely carrying a hazardous rating like Class I Div 2, Class I Div 1, IECEx/ATEX Zone 1 or Zone 2. But what does that mean exactly and how does this affect what lighting you should buy? Read on for more clarity on hazardous environments and ratings.

What is a hazardous location?

Hazardous locations are in more places than you think and it’s important to be aware of them if you are purchasing electronic equipment including LED lighting. Even your local gas/petrol station is considered a hazardous location because of the potential for an explosion. If, for example, a spark or lit cigarette collides with a drop or puddle of gasoline – FIRE! Your gas station needs hazardous-rated lighting.

According to UL (a US-based global certification laboratory), a hazardous location is “where explosion or fire hazards exist due to the presence of flammable gases, flammable or combustible liquid-produced vapors, combustible dust, or ignitable fibers or flyings.”

This could mean anything from the obvious like a drilling rig or chemical plant where highly flammable substances are mined or processed. Or it could mean the less obvious like a mill or sugar processing facility where the minute particles in the air have the potential to create a spark in the right conditions. Each facility is rated differently, based on their potential for explosion, which we’ll dive deeper into below.

What are some of the hazardous UL Ratings?

UL ratings are seen and adhered to most often in North America but do apply to countries in South America, Asia, and the Middle East. When looking at a hazardous UL rating, you’ll find the Class first and then the Division.

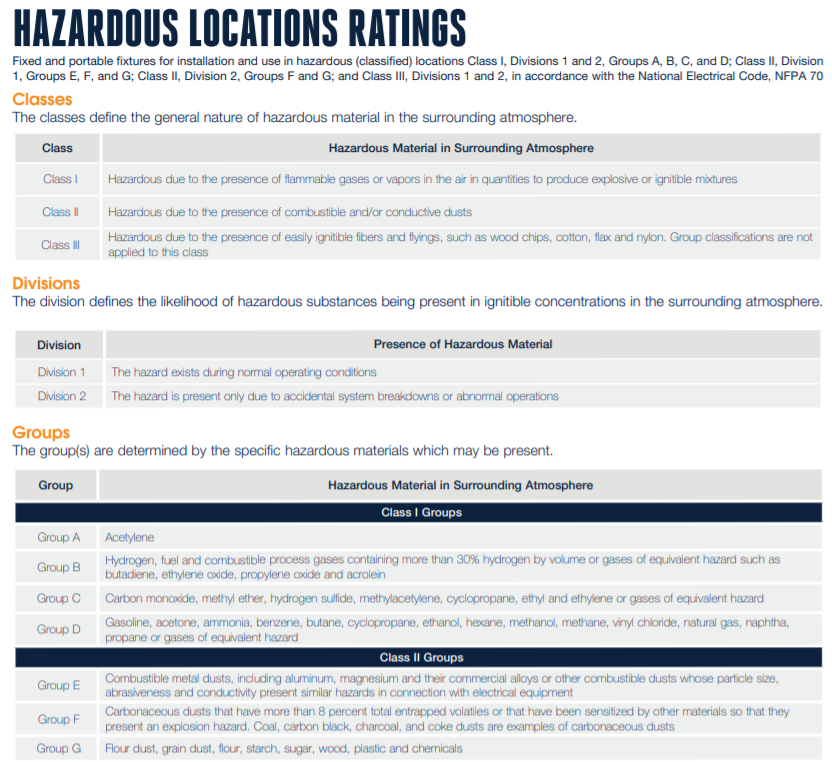

Dialight most often sees and certifies Class I, II, and III. The main difference between the three is the presence of flammable gases/vapors; combustible or conductive dust; or fibers like wood chips and cotton (see the chart below). The lower the Class the higher the hazard.

The Division (1 or 2) is what defines the likelihood of there being hazardous substances in enough ignitable concentrations in the atmosphere (i.e. what is the likelihood that there is enough gas or dust in a given situation that it would ignite or explode and what is the circumstance for that). If your facility is Div 1, it means that the particles or gases/vapors created at your facility are always potentially going to ignite and severe caution is needed to prevent a spark (think chemical processing). Div 2 means that an explosion or fire could only happen in the event of some breakdown or system failure but that extreme caution should still be observed to prevent catastrophe (ex. A platform in an oil refinery may be a CI D2 environment as the decks tend to be outdoors and far enough away from the source of the flammable gas. It would only become hazardous if an abnormal condition occurred like a valve failure or similar accident.)

What are some hazardous ATEX Ratings?

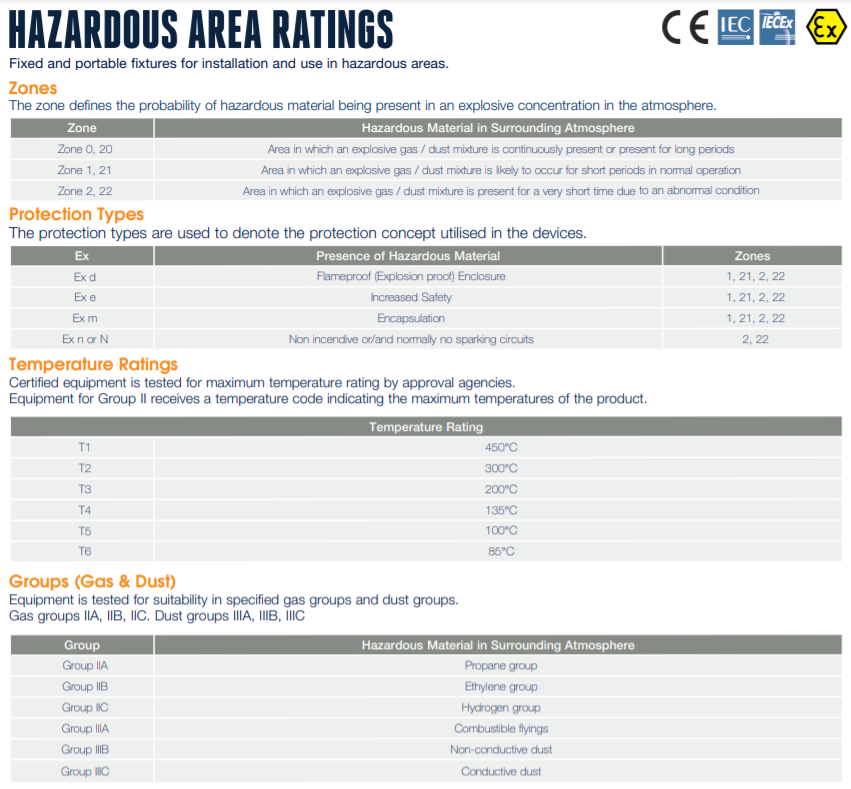

IECEx/ATEX ratings are seen most often in Europe, Australia, and parts of Africa, Asia, and the Middle East. They are relatively similar to UL ratings in that the lower the Zone the higher the probability is for fire or explosion based on the materials present and their concentration in the atmosphere. Both UL and ATEX classify certain substances in groups. Check out our ATEX reference chart below.

Since each sensor can provide individual feedback, it is possible to identify which guard-doors are open and which are closed. This is particularly useful when many sensors are connected in series.

Since each sensor can provide individual feedback, it is possible to identify which guard-doors are open and which are closed. This is particularly useful when many sensors are connected in series.

The YSM series is part of a range of non-contact safety sensors used to monitor guard-doors, hoods or covers. Thanks to non-contact switching and coded communication, the service life of these compact sensors is very long. Housings are ECOLAB-approved and rated to IP6K9K, making them suitable for washdown applications.

The YSM series is part of a range of non-contact safety sensors used to monitor guard-doors, hoods or covers. Thanks to non-contact switching and coded communication, the service life of these compact sensors is very long. Housings are ECOLAB-approved and rated to IP6K9K, making them suitable for washdown applications.

TECHNICAL DATA

TECHNICAL DATA