A well-known supplier of irrigation systems and water pumps. In addition, they also maintain agricultural machinery for farmers from the region. We had the opportunity to take a look at a recently delivered system. What we did not know beforehand was that we ended up in beautiful surroundings with stunning, colourful tulip fields.

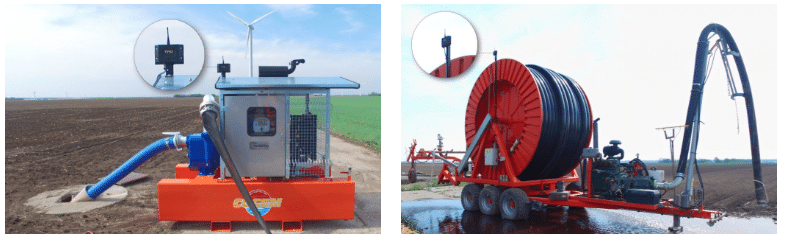

Cogem water pump and irrigation hose reel from AP

The mechanisation firm has already provided pumps from Cogem and irrigation drums from AP with our M2M system on a number of occasions. In their own workshop, they provide the pumps and reels with an Aquarius M2M transmitter.

Cogem is an Italian manufacturer that delivers generators and pumps on a global scale. Almost every pump has a remote control, which is brand-independent.

AP Mechanical Engineering specializes in the production of machines for the agricultural sector. The irrigation drums of AP are a well-known sight in the countryside. The M2M system, which is explained in more detail below, can also be applied to irrigation drums of other brands.

Operating the M2M system

The system works as follows: The irrigation reel is used to set the length of time the tulips are to be irrigated. As soon as no more irrigation is required, the system sends a signal to the receiver on the pump. The pump is then switched off.

Some systems also come with an additional hand transmitter. This allows you to manually adjust the number of speeds from the tulip field or switch off the system. The distance from the reel to the pump is, in many cases, several hundred meters. The farmer regularly has to move the sprinkler or switch it off. Nothing is more convenient than being able to do this remotely using a remote control.