Wireless Dozer Stop Switch

Enhancing Safety for Miners on Coal Stockpiles

At that critical moment, the dozer operators must rely on their ability to summon help quickly and reliably. The handheld CB radio in the dozer may not be enough if the signal cannot get through the coal pile. Wireless stop switches are now used to ensure continuous communication so emergency alerts can be sent and received immediately.

Fail-Safe Protection for Dozers on Coal Stockpiles

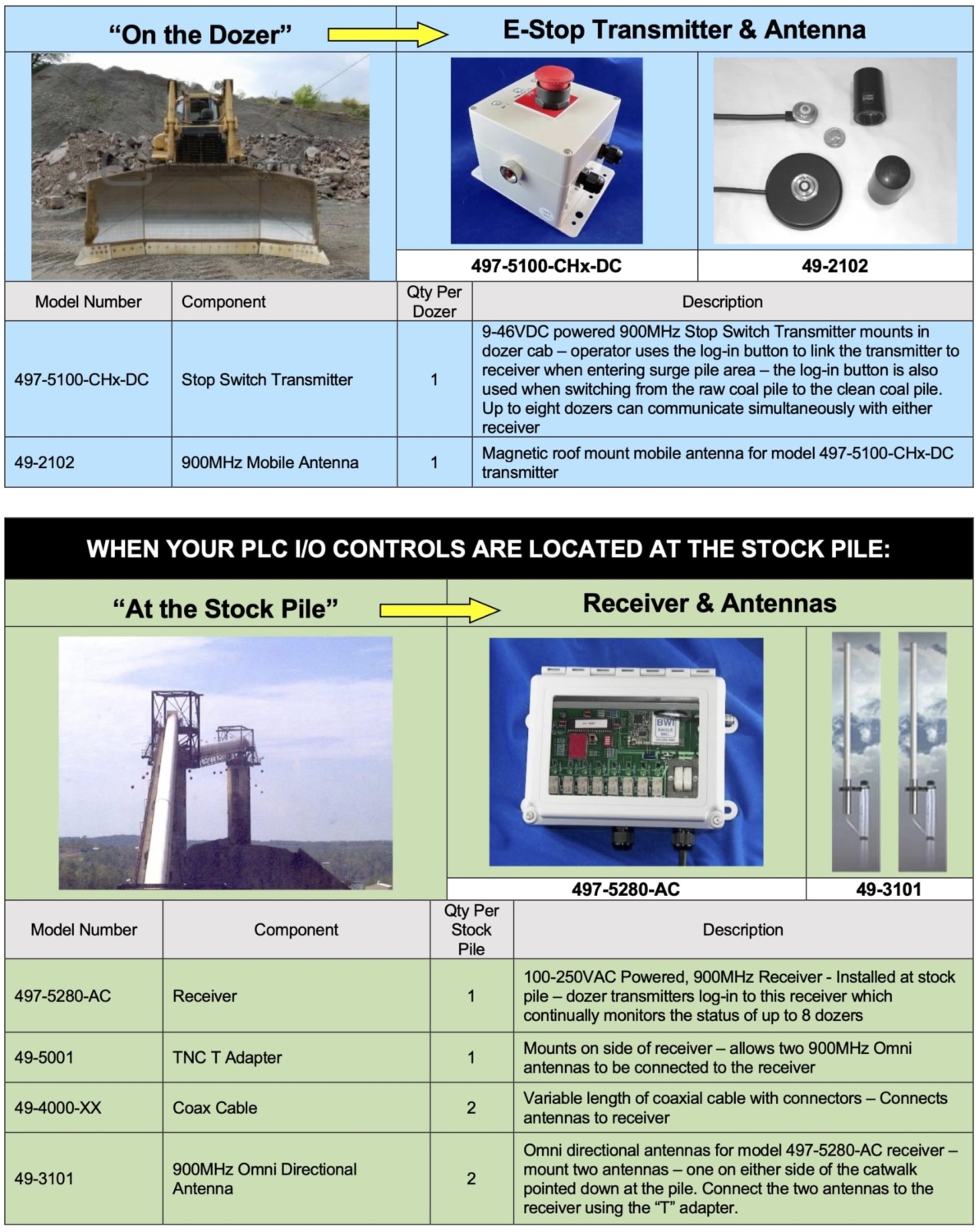

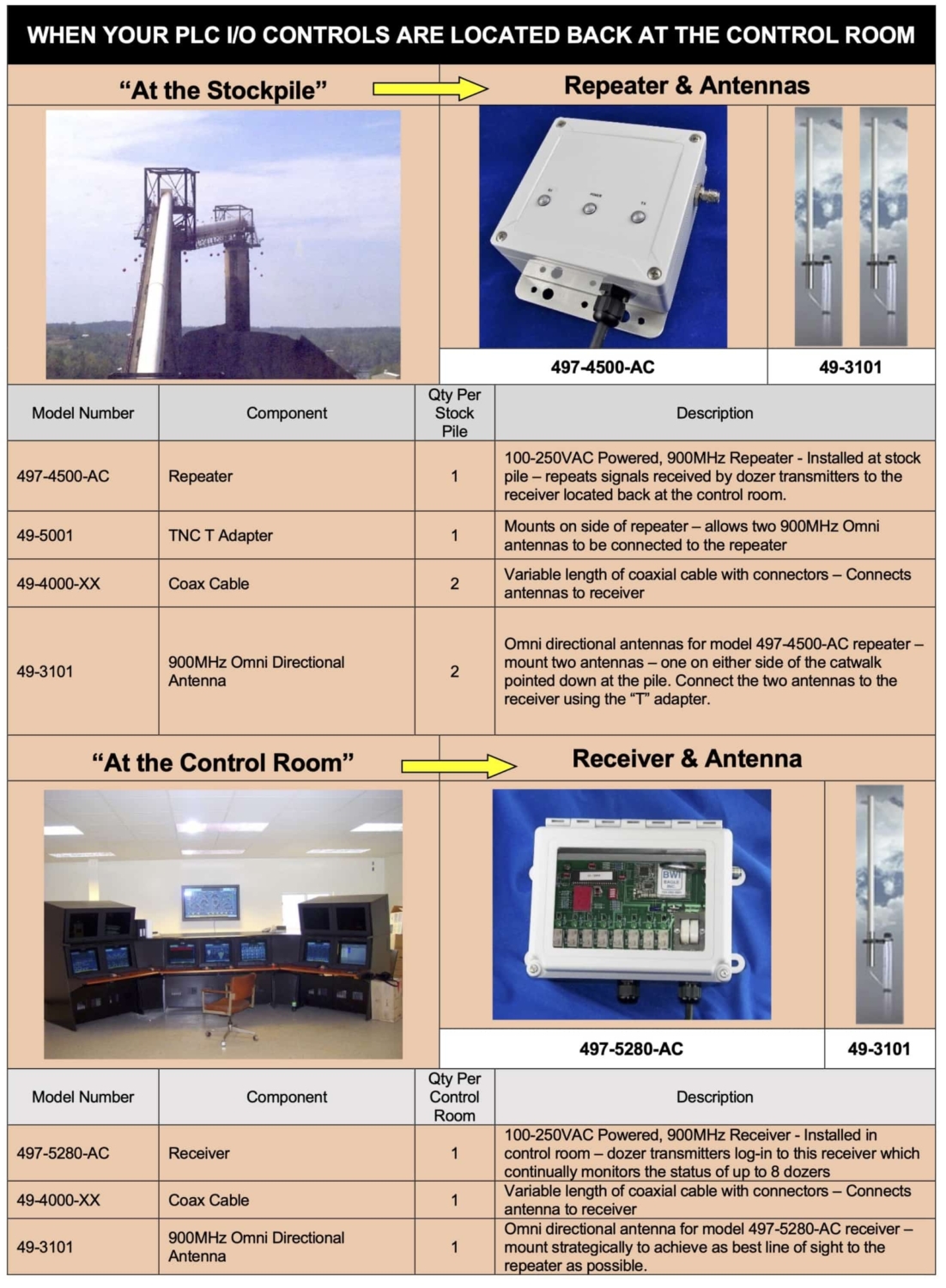

The BWI Eagle Dozer Stop Switch wireless system is purpose-built to enable dozer operators to stop the feeder and alert emergency personnel with a single button push from inside the cab.

The Dozer Stop Switch system redefines safety on coal storage piles by featuring a full duplex (handshake) link and an operating range of more than 4,500 feet.

If a dozer starts to fall into a cavity, the operator pushes the button to stop the feeder and alert emergency personnel. It also automatically stops if the handshake link is broken due to a signal loss or power failure, ensuring the feeder stops if the operator is unable to push the button.

The BWI Eagle Dozer Stop Switch is the only fail-safe protection for dozer operators working on coal stockpiles with underground feeders. The system features a continuous link between the dozer operation and the control PLC. Falling into a cavity would break the RF link and activate the e-stop as if the button had been hit.

Other RF systems rely on the emergency signal reaching the control receiver, but fail to consider that RF transmissions will not penetrate through layers of coal.

The system can monitor up to eight dozers simultaneously with a precise frequency auto-scanning signal that cannot be blocked or jammed. Integral high-current relays allow direct interfacing with other equipment and devices, while 900MHz spread-spectrum technology ensures the utmost security and reliability. When the operator logs in, onboard LEDs at both ends of the link verify that the handshake has been established, giving the operator and all other involved personnel a sense of confidence and trust.