The Importance of Black Channel Communication in Radio Remote Control

Radio remote controls are an integral part of modern manufacturing plants and operations. They allow operators to manage machinery and equipment from a safe distance while reducing the need for direct human interaction with potentially hazardous machines. Radio remote controls also enable precise equipment control, leading to improved efficiency and less risk of operator error. With additional protection like Black Channel Communication, radio remote controls become even more secure and reliable.

Overview of Black Channel Communications

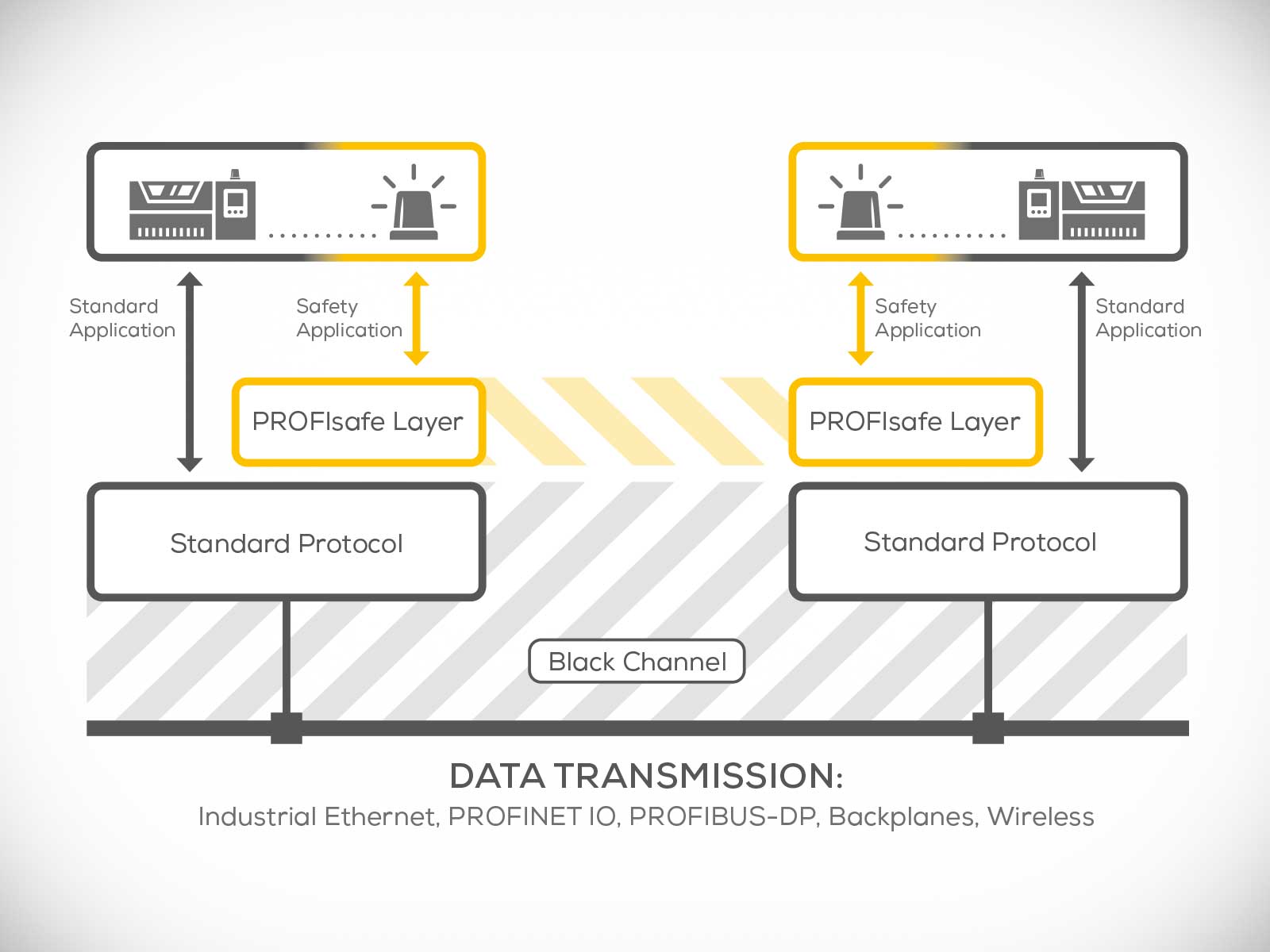

Black Channel Communication is a communication technology used to ensure the reliability of transmitted signals within control systems, particularly in manufacturing plants. This communication strategy involves the use of a functional safety protocol that operates on a separate, dedicated channel (the “black channel”) to verify the integrity of transmitted signals.

How Black Channel Communications Works

Black Channel Communication revolutionizes how signals are transmitted in control systems by utilizing a dedicated, functional safety protocol that operates independently of noncritical communication channels. This safety protocol inspects the integrity of signals sent across the ‘black channel’. Functioning independently ensures that even if the noncritical channel is compromised or experiences interference, the safety protocol remains unscathed, thus providing a failsafe mechanism.

How the Black Channel Enhances Safety

Another aspect of Black Channel Communication is the safety mechanisms to verify outgoing and incoming data sequencing. The sequencing mechanisms ensure that the correct data is processed in a very particular order. This technology is especially beneficial in high-stakes environments like manufacturing plants, where the slightest error or interruption can have far-reaching consequences. Its application is vital in systems where safety is paramount, as it can detect and react to any interference or corruption of the data.

Implementing Black Channel Communication can improve safety and efficiency metrics, especially in large manufacturing plants. For example, consider a plant experiencing occasional signal interference within its control systems, leading to sporadic operational glitches and potential safety hazards. With Black Channel Communication integrated into its radio remote control systems, the functional safety protocol can monitor the integrity of critical data, immediately detecting errors and taking necessary, safe approaches to correcting the problem. As a result, the instances of operational glitches will drop, thereby enhancing overall safety. Additionally, the newfound reliability of the plant’s control systems improves production efficiency by minimizing downtime.

Partner for Safe and Reliable Radio Remote Controls

Black Channel Communication is a technology that strengthens safety and efficiency within manufacturing plants and beyond. Ensuring the integrity of signals transmitted via radio remote control eliminates the risk of interference or corruption that can lead to operational glitches and potential safety hazards.

We selected radio remote controls enhanced with black channel communication to provide a robust solution for protecting control signals from unauthorized access or tampering. Products include Remtron and Safe-D-Stop.

Constant distance towards any metal

Constant distance towards any metal