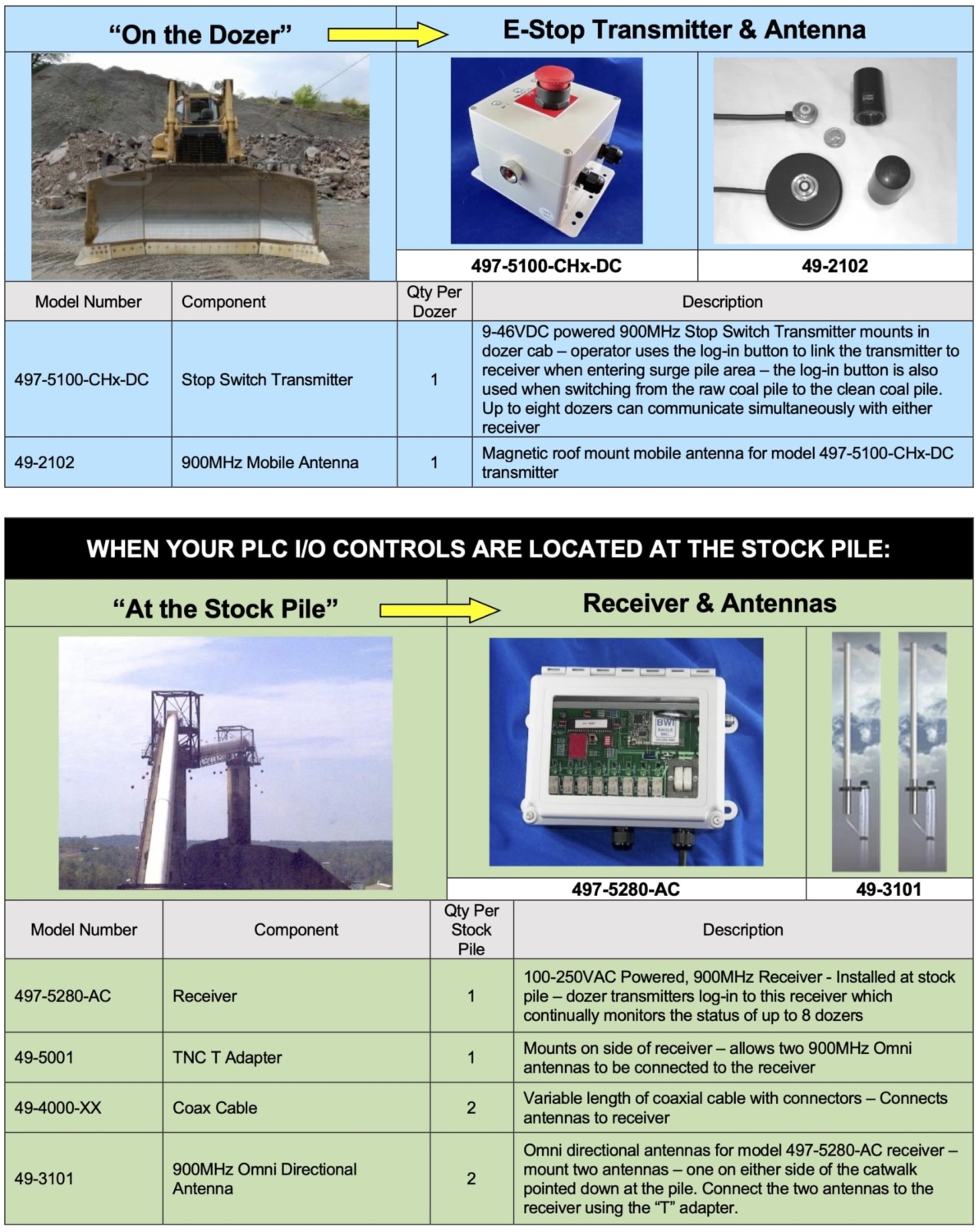

Optimizing Job Site Performance with Generator Control

In today’s fast-paced mobile equipment landscape, efficiency and reliability are key to maximizing productivity and return on investment. One of the most impactful advancements in this regard is the ability to automatically start and stop generators supplying power to mobile and rental equipment. This capability optimizes job site performance and significantly increases operational efficiency, leading to a higher rate of return on investment.

Importance of Reliable Communication

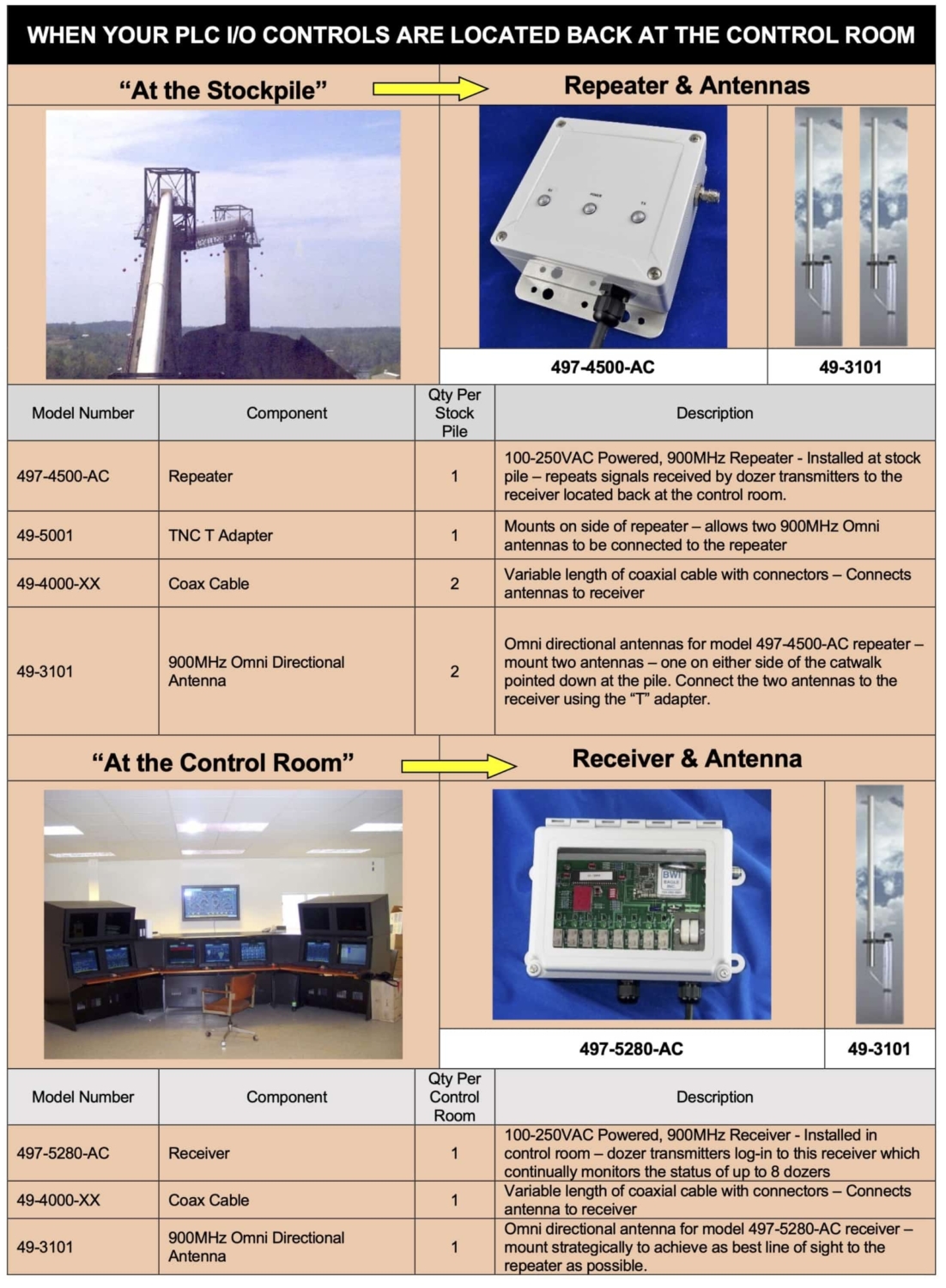

Reliable communication between the controller and the generator is crucial for generators to function effectively, especially those that are mechanically or electronically governed. Any lapse in communication can lead to downtime, reducing productivity and increasing costs. Ensuring seamless interaction between the control systems and the generators is paramount for maintaining a consistent power supply and operational efficiency.

Durability in Harsh Environments

Generators often operate in challenging environments, exposed to harsh weather conditions such as rain, snow, dust, and extreme temperatures. Controllers used to power these solutions must be exceptionally durable and designed to withstand these elements. Robust construction and advanced engineering ensure that these control systems can perform reliably, no matter the environmental conditions.

Efficient Controllers for OEMs

By integrating advanced controllers into mobile generators, Original Equipment Manufacturers (OEMs) can monitor and manage generator performance from virtually anywhere. This integration offers several significant benefits:

Better Management of Start/Stop Times: Control solutions enable precise management of when generators start and stop, optimizing their use and reducing unnecessary run times.

Fuel Consumption Adjustment: Efficiently managing fuel consumption is critical for cost savings. Advanced control systems can adjust fuel usage based on real-time data and operational needs.

Issue Diagnosis: Early detection and diagnosis of potential issues can prevent costly breakdowns. By adding telemetry devices with remote monitoring capabilities, controllers allow for real-time diagnostics, helping to identify and address problems before they escalate.

Reducing Downtime and Increasing Efficiency

One of the most significant advantages of integrating control solutions into mobile generators is the reduction of downtime. With real-time adjustments, these systems ensure that generators are always operating at their best. This reliability translates into less downtime for mobile equipment, enhancing overall job site productivity.

The ability to manage generators brings a new level of efficiency and reliability to job sites. OEMs can achieve significant cost savings and operational improvements by ensuring robust communication, durability in harsh environments, and comprehensive remote monitoring. These advancements enhance performance and provide a competitive edge in today’s demanding industrial landscape.

Generator Controllers

DynaGen™ PRO600

|

DynaGen™ TG410

|

DynaGen™ TG350

|

DynaGen™ RA400

|

DynaGen™ Retro Kit

|

|

Telemetry Devices

Messenger BLE

|

Messenger Lite

|

VisiTek™ 600

|

Monitoring Services

Four-button handheld transmitter

Four-button handheld transmitter

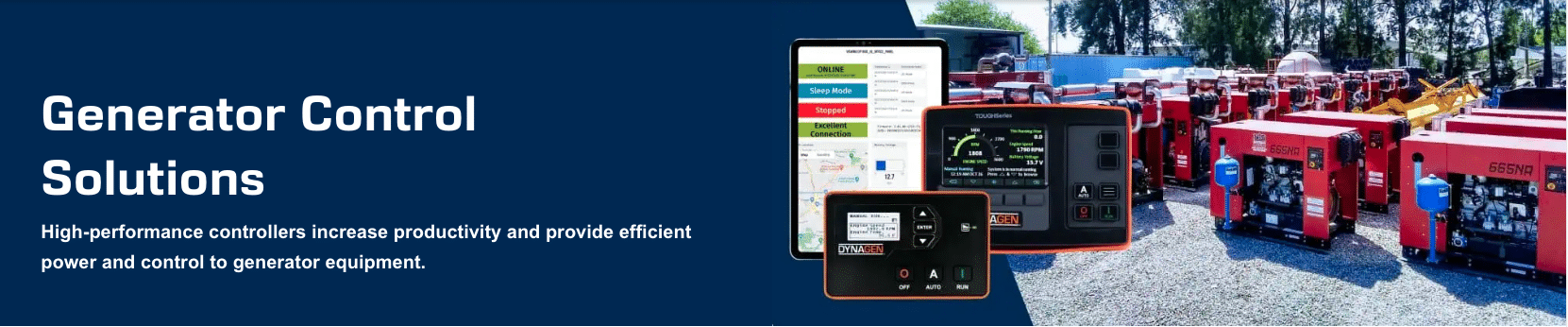

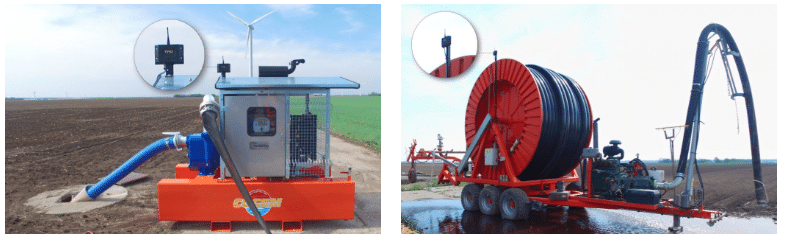

The most significant concern on a coal storage pile is the risk of a dozer falling into the feeder cavity. This occurs when unseen pockets develop in the pile and collapse, swallowing the dozer. The operator’s safety and protection depend on how fast the feeder can be stopped and emergency personnel alerted.

The most significant concern on a coal storage pile is the risk of a dozer falling into the feeder cavity. This occurs when unseen pockets develop in the pile and collapse, swallowing the dozer. The operator’s safety and protection depend on how fast the feeder can be stopped and emergency personnel alerted.