Mobile Conveyor Control Systems

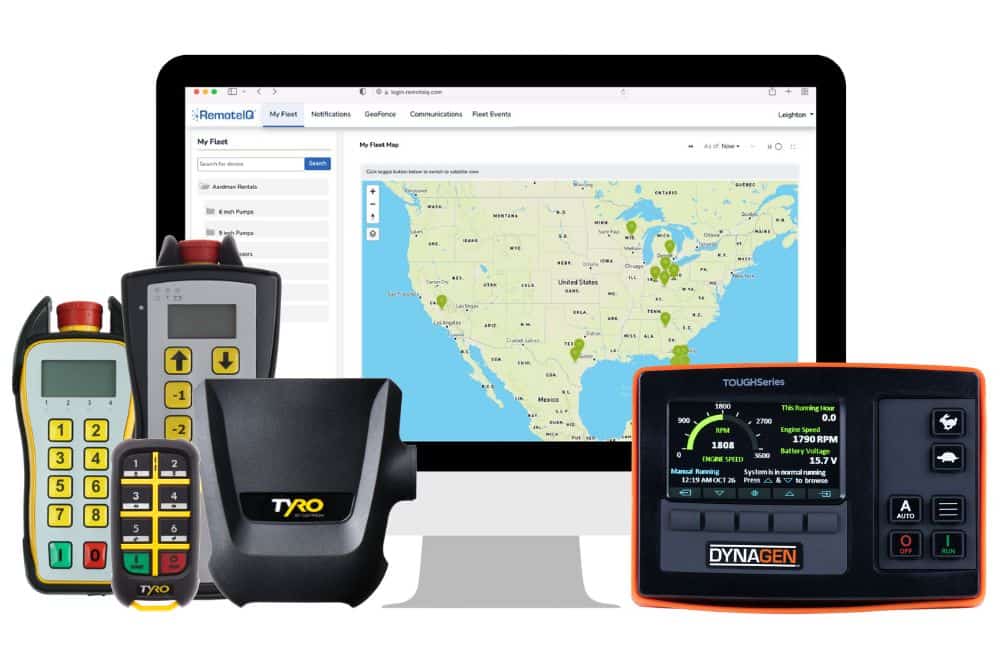

Learn how DynaGen controllers, Tyro radio remote control and Messenger telemetry products can be used to create an integrated control solution.

Mobile Conveyors Provide Flexibility and Efficiency

Mobile conveyors are widely used in agriculture, aggregate production, construction, and mining and offer a range of benefits that can be greatly enhanced with wireless automation and tight integration to engine and machine control. Combined with engine and machine control solutions, mobile conveyors become easily adjustable, allowing for quick adaptation to changing process needs. A mobile conveyor enabled with wireless automation can improve production capacity while providing a wider field of view, enhancing safety for operators when transporting hazardous materials.

Integrated Controls Can Boost Productivity and Safety

Operating mobile conveyors efficiently requires intelligent machine control systems to effectively control and regulate movement and overall performance while enhancing operator safety. Utilizing Cattron’s application engineering expertise and an integrated controls approach will result in optimized control over the conveyor’s speed, direction, and material-carrying capacity. The system architecture can be set up to enable a radio remote control option. Wireless remote controls allow operators to interact with the conveyor without any physical interface, boosting safety and efficiency. Incorporating our cloud-based telematics solutions can add another level of intelligence, enabling real-time monitoring, remote diagnostics, and machine tracking.

The Cattron integrated controls approach can add significant value to your business. Machine operators will benefit from our market-leading technology and system expertise:

- Integrated DynaGen™ engine controllers offer end users reliable control over engine performance in extremely harsh environments. They are a central point of monitoring for warnings and failures, providing seamless engine and conveyor control integration. DynaGen controllers can transform mechanical systems into a J1939 gateway and enhance the communication interfaces to other devices and systems.

- Tyro™radio remote control solutions offer end users a way of controlling speed, direction, height, and on/off functions without being at the control panel, increasing operator safety.

- Cloud-based monitoring with RemoteIQ™ allows end users to track high-value equipment through GPS location monitoring and provides remote equipment visibility and oversight through intuitive dashboards and alarm notifications.

Choosing the Right Engine Control Partner

Our integrated solutions are designed to meet the needs of both machine OEMs and end users. We offer durable plug-and-play engine controllers and panels, including rapid prototyping, variable speed capabilities, wireless remote control modules, cloud-based remote monitoring and diagnostics. In addition, our CANbus-based hardware seamlessly connects everything, using optimized wire harnesses, sensors and HMI products.

Our comprehensive approach means we work closely with the Engine OEM and the Machine OEM to boost productivity, ensure maximum uptime and prioritize safety.

Contact us for a consultation.

Integrated Mobile Conveyor Control

A comprehensive solution incorporating DynaGen engine controllers with a Tyro wireless remote control for safety.

Leave a Reply

Want to join the discussion?Feel free to contribute!