Description

Dynapar OnSite™ Online Condition Monitoring System

Cut costs and boost productivity with a condition-monitoring tool designed for ease of use and scalability. The Dynapar OnSite™ system is a powerful predictive maintenance system targeted at preventing failures before they occur. It can slash unscheduled downtime, improve the efficiency of route-based vibration analysis, and provide real-time analytics and trending to warn of possible machine failures.

Dynapar OnSite™ Hardware

Dynapar OnSite™ Hardware

Affordable, 24/7 condition monitoring

Easy to deploy and easy to use by anyone

No custom gateway or large upfront investment required

Easy to expand, scale and redeploy to other assets

Tough enough to survive the harshest conditions

Setup in minutes, no need to wire into control architecture

Triaxial accelerometer sensors collect integrated vibration, temperature and speed data (with optional encoder input)

Learn more about Hardware

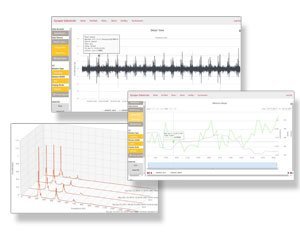

Dynapar OnSite™ Analytics

Easy to use alarms send alerts via text or email

Cloud-based, access from any device

Built-in tools including FFT plots, waterfall plots, harmonic cursors, RMS trend and more

Designed for multi-stakeholder access

Supports both vibration analysis experts and non-experts

Learn more about analytics

Access Critical Data from Anywhere

Access Critical Data from Anywhere

The Dynapar OnSite™ System monitors speed, acceleration, temperature and vibration data. Alarms can be set and correlations can be drawn to a machine’s running conditions to detect a change of state via the cloud.

Affordable, Even to Monitor Only 1 Point

Even the smallest motor can cause downtime. The Dynapar OnSite™ System is the first product in its class that offers powerful condition monitoring at an accessible cost with no large upfront investment so you can monitor any asset affordably.

Easy to Deploy and Use by Anyone

The Dynapar OnSite™ System units can be installed and configured in less than 30 minutes. Wi-Fi or cellular communication eliminates wiring and browser-based analytics means no adjustments to control architecture.

Easy to Scale or Transfer to Different Assets

With a Wi-Fi or cellular network, one 4-point system is affordable to monitor any machine and more units can be added to monitor more assets. Existing units can be easily transferred to different assets.

Enable Real-Time Collaboration Across the Whole Team

Secure cloud-based analytics can be accessed by anyone on the team and is independent of control data allowing maintenance, operations and vibration professionals to collaborate and make timely decisions.

Built for Tough Environments and Remote Locations

The Dynapar OnSite™ System is designed to survive in harsh environments that may be dangerous or too remote to send route based teams on a regular basis.

|

Condition Monitoring System Overview Learn more about the Dynapar OnSite™ Condition Monitoring System, view key features and download datasheets. |

|

Online Condition Monitoring Process Discover how the Dynapar OnSite™ system can change the way you monitor critical assets and eliminate data silos within your organization. |

|

Condition Monitoring Applications See examples of how plants of all sizes use the Dynapar OnSite™ System to detect problems before they occur, monitor assets and make decisions. |

Dynapar OnSite™ Hardware

Dynapar OnSite™ Hardware Access Critical Data from Anywhere

Access Critical Data from Anywhere