Description

Visit Ranger System Pages: Handheld | Ranger 3 | Ranger 4 | Ranger 6 | Servo Linear Actuator

Our belly pack RANGER systems are a simple, cost-effective way to retrofit a wireless remote on a manual hydraulic system with 4 to 6 axes of variable speed control.

The package is supplied with electrical actuators to stroke the valves in both directions, and all hardware to connect the actuators to the valve handles or linkages. The actuators are connected to the receiver with a pre-made harness.

The belly pack RANGER is fast and smooth; it responds in 0.05 seconds and feathers all of the crane functions. Installation is simple with our illustrated manual.Four or six proportional paddles control the winch and boom, and additional toggle switches drive the auxiliary functions and boom speed selection. There is a key switch mounted on the side for turning the transmitter on and off, as well as starting the engine. Side-mounted, sealed pushbuttons are used for increasing and decreasing the engine RPM, as well as for the horn. Enable buttons are on the transmitter and are required to be pressed in order to operate the crane, as a safety feature along with the Emergency Stop switch. The belly pack transmitter has the ability to run over an included tether cable in the event of a dead battery, and all functions can be manually controlled on the receiver/control box, or even using the manual levers.

Our radios are proven safe and secure. The CAN actuators that control the valves are fast and precise to 0.01” with 90 pounds of force. They are environmentally hardened for all weather. An internal clutch allows local operation of the valve handles without any effort when not in active wireless operation. This control is tough – all electronics are silicone dip-coated or encapsulated, every switch, joystick, and enclosure is sealed, and the transmitter is molded out of a high-impact rated plastic ready to take a beating on a job site. If you need additional functionality, custom configurations are available by request.

Each Bellypack RANGER System includes the following components:

PACKER Series Radio Transmitter

The PACKER transmitter is molded out of a high-impact plastic that’s durable from -40 to 185F (as are all components, including the electronics!). It contains switches for winch speed, and boom speed, and two for basket leveling (or use them for an auxiliary function).

It has either four or six fully-proportional paddles for smooth control of your winch, boom elevation, boom rotation, and boom extension. The six-paddle version adds paddles for upper and lower boom elevation and extension, usually for knuckle-boom cranes. There are enable horns, RPM pushbuttons, an E-Stop switch, and a three-position key switch for power and engine start – just like your car.

It runs off of internal rechargeable batteries that provide approximately 20 hours of operating life between charges. A high-quality padded shoulder strap is included.

000

000

000

Radio Receiver

This radio receiver module directly drives the actuators, crane switches, and all engine functions with two simple plug-and-play front-panel mounted sealed connectors. It provides all outputs based on transmitter commands. The ARM-powered receiver is housed in a sealed polycarbonate enclosure with industry-standard sealed Deutsch connectors. All I/O are protected against reverse battery connections, transient voltage spikes, short circuits, and overload.

The system has an onboard backlit 2×16 character display for easy setup and configuration, manual backup, diagnostics, calibration, and histogram, driven by four sealed pushbutton switches. In addition to driving the actuators, it has multiple outputs for various throttle control types, and outputs for engine start, engine stop, horn, and basket tilt (or auxiliary). RS-232 is on-board for configuration as well.

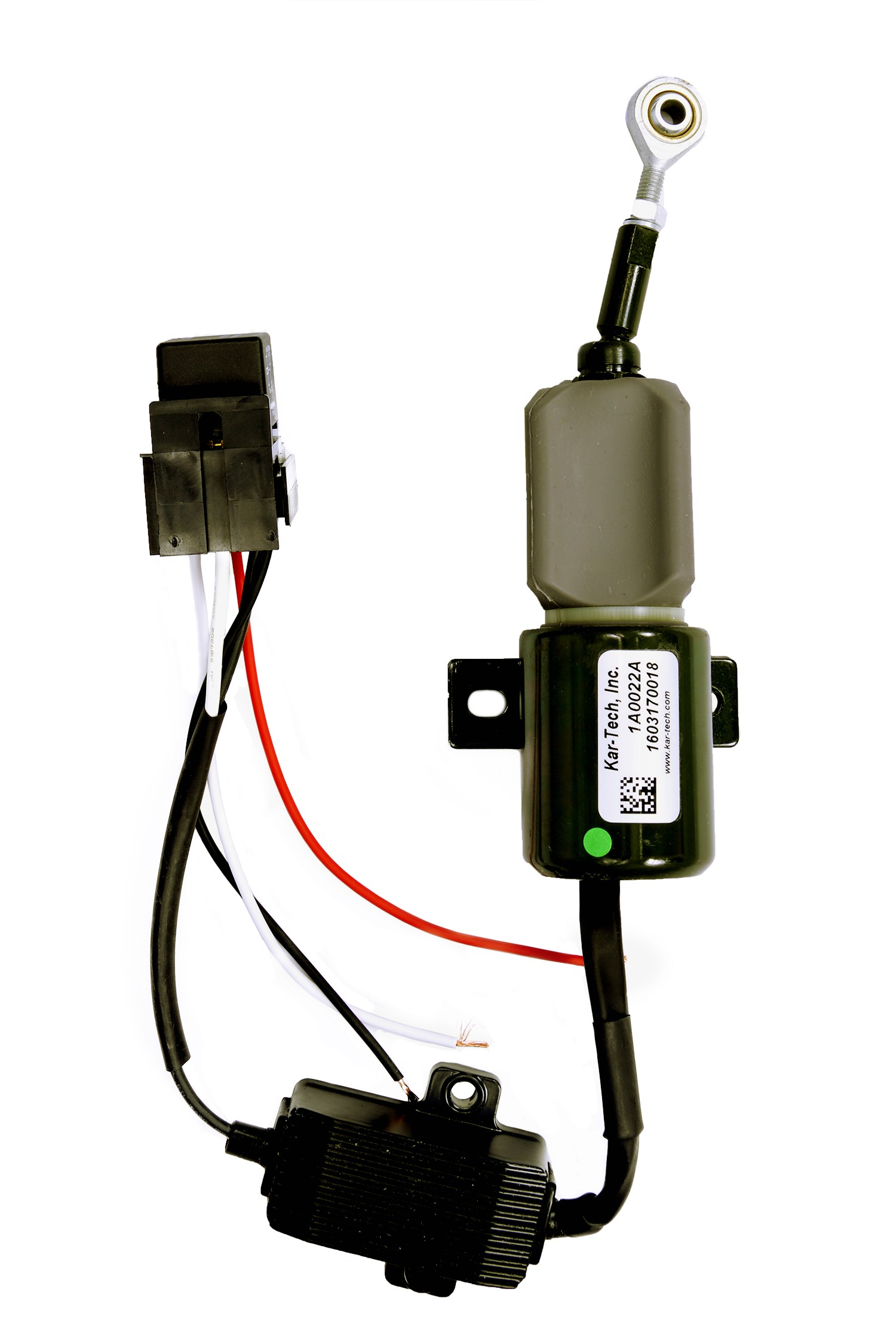

12/24V Linear Actuators

These CAN-enabled actuators provide 90 inch-pounds of force with a 3” maximum stroke and built-in processor for precise control of hydraulic valves. They have an internal clutch to enable freewheeling back to the center position when the joystick is released or power is lost as a safety feature, and are fully weather-sealed.

Mounting Hardware Kit

This kit is comprised of adjustable linkage rods and clevises for connecting the actuators to the valve handles. The steel bracket is supplied by the installer.

Pre-Made Wiring Harness

This pre-made harness is designed to snap into each system component for an effortless installation with two sealed toggle switches for left and right pedestal remote power. All wires and connectors are labeled for easy identification. All sealed connectors are used, and cables are loomed together where required for a clean, plug-and-play installation. Crane connections such as RPM, horn, etc. are terminated in flying leads.

000

Throttle Pull Actuator

Our Throttle Pull Actuator is a simple, low-cost actuator meant to pull an engine throttle lever high or low. It’s rated for 12V use, draws 50A for 0.7 seconds to pull, then holds with a 1A current draw. It has a 1″ stroke, pulls with 11 pounds-force, then holds at 36 pounds. The actuator is packaged with a driver, and socketed relay with wire leads ready for you to plug in power, ground, and a pull signal.

000

External Harness Actuator Y Cable

External Harness for 12/24V Linear Actuator / Throttle Actuator (P/N: A1A0014C). This harness is used when adding additional actuators to the Ranger system.

Check out how easily we retrofit this TEREX BT-3870-S Crane

with our CAN RANGER 4: Bellypack Ranger System.