Description

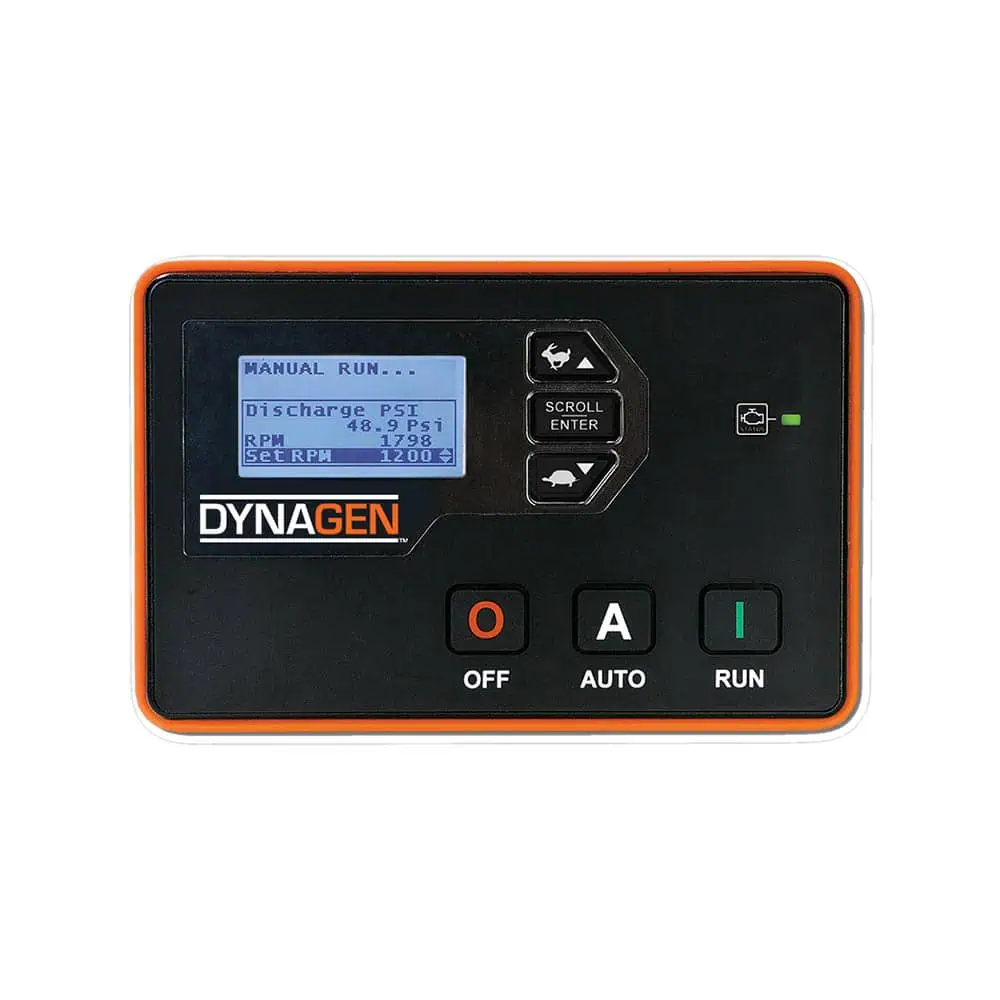

The TOUGH Series® TE controller is designed for variable-speed engines used in applications that require dependable operation over long periods, such as pumping, irrigation, compressors, power units, and material processing equipment.

The TE controller is ideal for remote applications where robustness and dependability are critically important. It can be easily configured for either mechanical or electronic CANbus engines.

The DynaGen™ TE410 supports variable speed applications and closed-loop control for mechanically or electronically governed engines.

It offers autostart or manual operations, CANbus communications, nine inputs, and six outputs.

Private label branding is available for OEMs.

Housing

- Conformally coated for protection against moisture and contaminants

- Front panel gasket for panel water ingress protection

Display

- Oil pressure and engine temperature

- Fuel and oil levels

- Hour meter

- RPM

- Battery voltage

- Real-time clock with date/time

- J1939 DTC codes

- DPF and DEF status icons

- J1939 percent load and percent torque

- Custom screens for pumping or compressor applications

RapidCore Software

The easy-to-use software interface allows you to set up your controller, adjust configurations, customize CANbus settings, and download diagnostic details. Download the latest software version.

Autostart

Autostart trigger on sensor value (pressure, temperature, level voltage)

Functions

- Built-in weekly scheduler

- Maintenance counter

- Preheat and many configurable timers

- Stall detection

- Retry on false start

- Custom warnings and failures

- Configurable Diagnostic Trouble Code (DTC)

- Load imbalance detection

- IDMT overcurrent protection

Speed Control

- Front panel RPM adjustment buttons

- Full electronic variable speed control over J1939

- Configurable remote bump speed control

- Configurable ramping control with 3 set points: idle, intermediate, and goal RPM

- Adjustable min/max RPM limits

- Configurable set point RPM output feature

AC Current Sensing

For electric-driven equipment

Closed Loop Control

Closed loop control using feedback from sensors such as level and pressure.

Inputs / Outputs

Four analog inputs, five digital inputs, and six switched outputs

Communications

- CANbus J1939

- Modbus RS-485

ISO Certification

- Manufactured in an ISO 9001:2015 certified operation