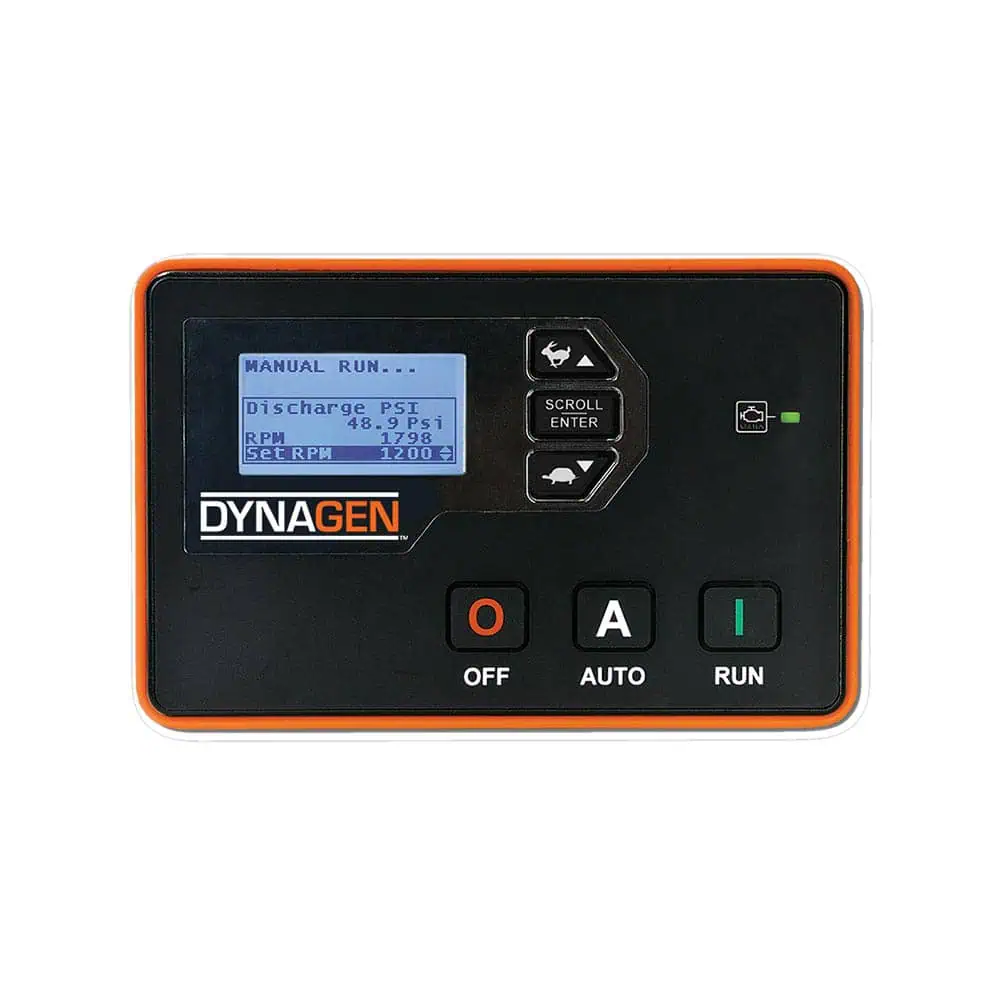

Description

Housing

- Conformally coated for protection against moisture and contaminants.

- Front panel gasket for panel water ingress protection

Display

- Oil pressure

- Engine temperature

- Fuel and oil levels

- Hour meter

- RPM

- Battery voltage

- Real time clock with date/time

- J1939 DTC codes

- DPF and DEF status icons

- J1939 percent load and percent torque

- Custom screens for pumping or compressor applications

Autostart

Autostart trigger on sensor value (pressure, temperature, level voltage)

Functions

- Built-in weekly scheduler

- Maintenance counter

- Preheat and many configurable timers

- Stall detection

- Retry on false start

- Custom warnings and failures

- Configurable Diagnostic Trouble Code (DTC)

Speed Control

- Front panel RPM adjustment buttons, full electronic variable speed control over J1939

- Configurable remote pump speed control

- Configurable ramping control with 3 set points: idle, intermediate, and goal RPM

- Adjustable min/max RPM limits

- Configurable set point RPM output feature

Closed Loop Control

Closed loop control using feedback from sensors such as level and pressure

Inputs / Outputs

Four analog inputs, 5 digital inputs, and six switched outputs

Communication

CANbus J1939

ISO Certification

Manufactured in an ISO 9001:2015 certified operation

Options

RelayPak

Snap-on RelayPak eliminates the need to mount and wire external slave relays for fuel crank and up to two other loads

Monitoring

RemoteIQ remote monitoring and control are available with a cellular modem

Mimic Panel

TR100E is available for TE350 and TE410 controllers and mimics what is displayed on the controller.