Description

Engine and Generator Controllers

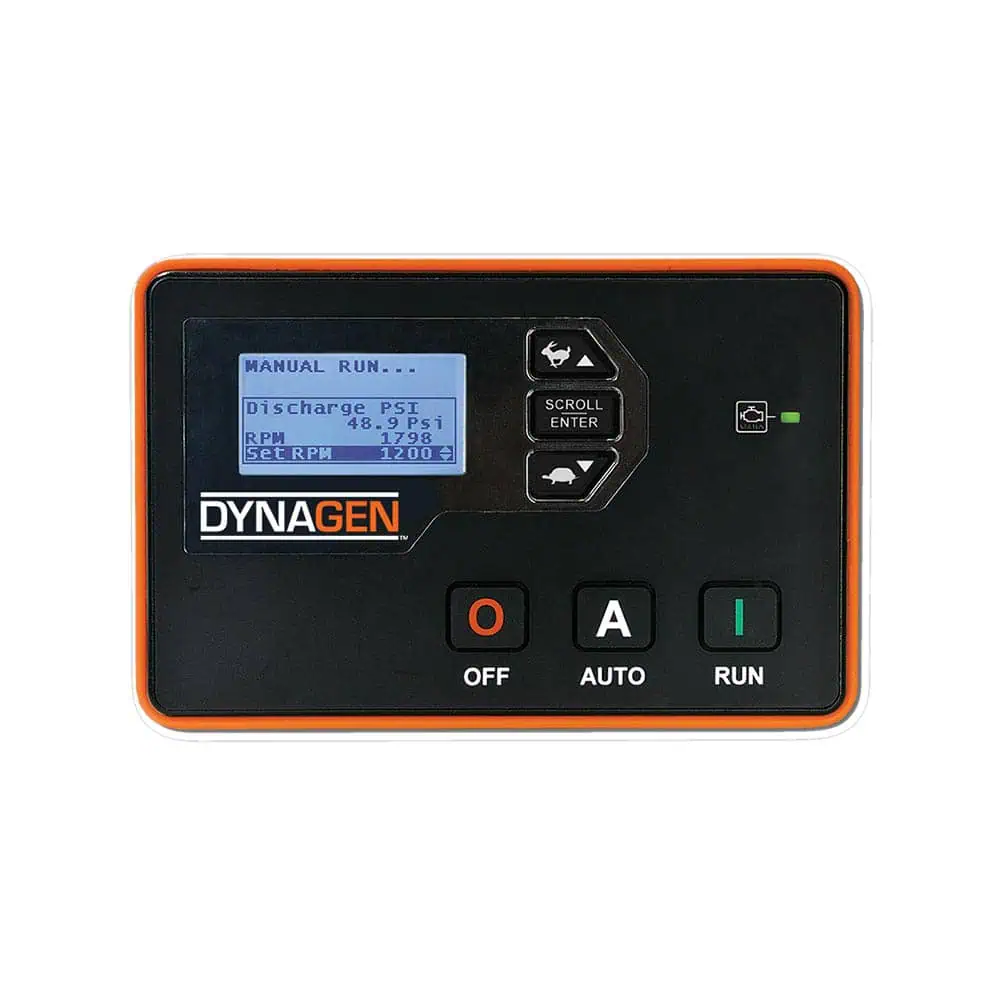

DynaGen™ engine and generator controllers automatically start/stop, monitor, and protect equipment, engines, and machinery and are designed to survive extreme temperatures, vibration, and shock. They use superior automotive-grade plastics, high-heat laminates for circuit boards, resilient silicon front panel buttons and undergo the most demanding SAE Heavy Truck and MIL standards.

When it comes to system design, DynaGen controllers are very flexible, straightforward to configure, and easily integrated into engine and machine OEM products to maximize uptime and prioritize safety.

Manual and remote start/stop, speed control, hour meter, engine temperature, battery voltage, and fuel and oil levels can all be managed remotely to save time and money on maintenance and services and reduce equipment downtime. Controllers are supported by the RemoteIQ™ cloud-based remote monitoring platform to enable convenient and seamless monitoring and control of equipment from anywhere.

DynaGen controllers can be seamlessly integrated with CANbus-based hardware with harnesses, sensors, and HMI products for engines and generators in the mobile equipment market. Typical applications include mobile conveyors, excavators, harvesters, mulchers, light towers, skid steer loaders, vacuum trucks, and rock crushers.

PRODUCTS

|

Reasons to Choose DynaGen

Customers prefer DynaGen controllers for their ruggedness and ability to withstand harsh environments.

MARKETS & APPLICATIONS

- Industrial Automation

- Equipment Rental Operators

- Mining

- Material Handling

- Oil and Gas

- Mobile Equipment

- Rail Operations

- Water Management

- Agriculture

- Power and Fluid Solutions