Description

Transformer Monitoring

- Advanced Electronic Temperature Monitor (ETM)

- Direct Oil Temperature

- Simulated Winding Temperature

- Calculated Winding Temperature (CT Models)

- LTC Temperature Difference (LTC Models)

- Single, Dual, and Three Channel Units

- Analog & Digital Inputs

- Multi-Stage Fan/Pump Control

- Weatherproof Metal Case

- SCADA Ready – DNP3.0 & Modbus Protocols

Made in the USA

The Transformer Advantage is a precision temperature monitor for liquid-immersed power and distribution transformers. It is rugged, fully electronic, and field configurable. With Transformer Advantage, users can extend transformer life, utilize maximum capacity and reduce maintenance costs.

Seven models in the Advantage line offer a range of functions and configurations. All use an accurate and stable platinum temperature sensor (RTD) to measure critical liquid temperatures precisely. Setpoint relays can activate alarms or multiple stages of cooling at different temperatures.

7 Models Make It Easy to Upgrade to the Transformer Advantage

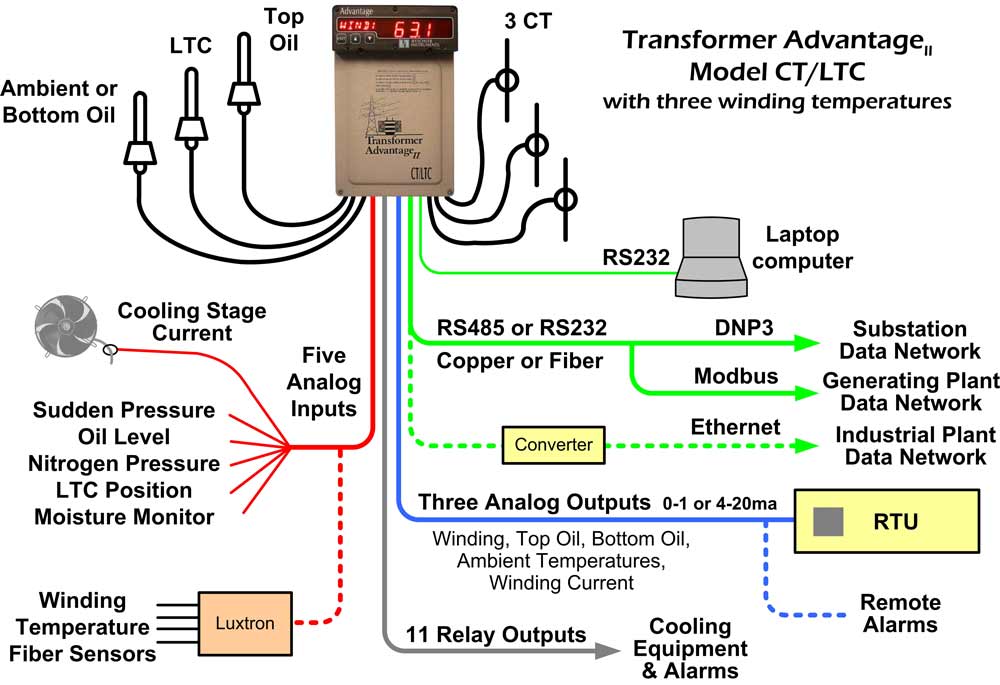

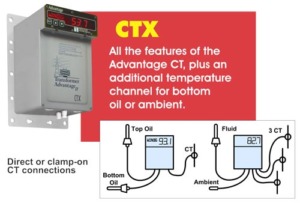

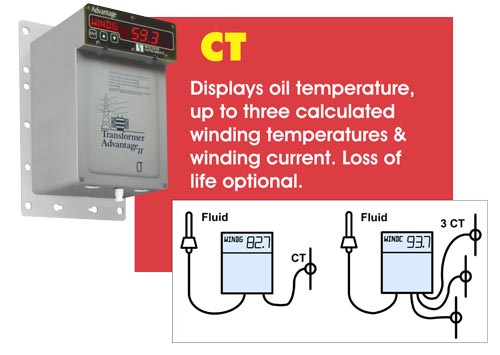

The CT, CTX & CT/LTC models measure top oil temperature and winding current to calculate winding temperature. They are ideal for new and installed transformers where heat run data is available.

The DC, TC, and SC models utilize a heated thermowell to measure winding temperature. This simplifies installation on existing transformers, particularly when upgrading from analog gauges.

The LTC model monitors the load tap changer temperature and the temperature difference between the LTC tank and the main tank.

|

The Transformer Advantage is a precision temperature monitor for liquid-immersed power and distribution transformers. It is rugged, fully electronic, and field configurable. With Transformer Advantage, users can extend transformer life, utilize maximum capacity, and reduce maintenance costs. |

|

Seven models in the Advantage line offer a range of functions and configurations. All use an accurate and stable platinum temperature sensor (RTD) to precisely measure critical liquid temperatures. Setpoint relays can activate alarms or multiple stages of cooling at different temperatures. A sequencing function equalizes run time between cooling stages. The fan timer can exercise fans at a preset time each day. A seasonal setback is available on any set-point relay. A front panel test mode quickly verifies cooling and alarm operation. The high current relay contacts can be configured to fail-safe (close on monitor fault or power fail). |

|

The large alphanumeric LED display continually shows the selected transformer parameter. Front panel buttons scroll the display through other parameters and relay/alarm status. Peak and valley values for each channel are time-stamped and stored in non-volatile memory. These are easily checked and reset by the operator from the front panel or through digital communications. A password-protected supervisor mode accesses all setup parameters. Initial setup can be done from the front panel or through either an isolated communication port (wire or fiber). Windows-based configuration software significantly speeds up startup. |

|

The Transformer Advantage 3 is a cost-effective upgrade from analog gauges and an easy upgrade from Transformer Advantage II. It is designed to be mounted on the transformer or in the control cabinet. Probe options fit most popular thermowells or magnetically mount on units without wells. The Advantage has been conservatively designed and stress-tested to provide years of trouble-free service in the harshest environments. A wide variety of options tailor the Transformer Advantage 3 to each application.

|

| Simulated Winding Temperature

This is the traditional method for indicating transformer winding temperature. A heated thermowell, driven by a bushing CT, simulates the winding temperature rise above the oil temperature. This temperature rise is calibrated by the transformer manufacturer at full load. Performance is optimized for steady state or slowly changing loads. The simulated winding method is often used as a direct replacement for an analog winding gauge when higher accuracy, more configuration flexibility, or a SCADA interface is required. One, two and three-channel Advantage models support this method on new or existing transformers.

|

Calculated Winding Temperature

A newer method uses oil temperature and load current to calculate winding temperature, based on IEEE guidelines. The Transformer Advantage analyzes transformer parameters to determine thermal time constants for the oil and windings. These time constants are changed dynamically based on load and cooling conditions. The rate of change information is also utilized in the Weschler CT algorithm to further improve the winding temperature accuracy. This is particularly important when operating above nameplate rating. Three Advantage models use the CT method for winding temperature indication.

|